Our Products

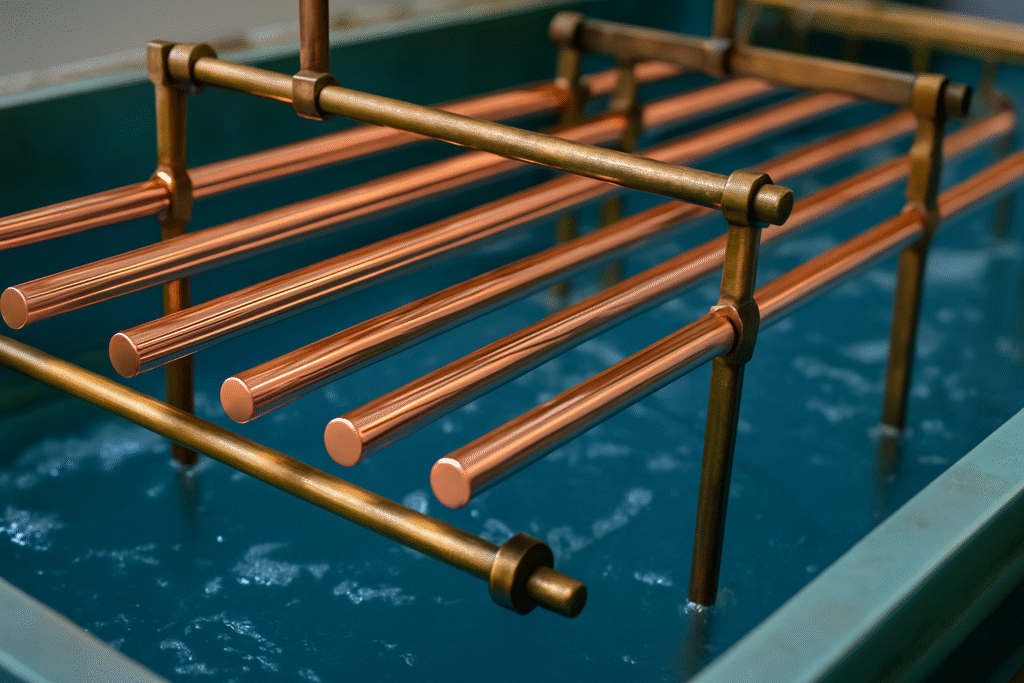

Copper Plating Solution

Product Overview

Tahir Chemicals’ Copper Plating Solution is specially engineered to meet the demands of industries seeking high-performance, durable, and uniform copper coatings. Whether you’re preparing components for decorative finishes or building a foundation layer for multi-metal electroplating, our solution ensures optimal results with precision and reliability. Designed for both rack and barrel plating systems, this product delivers high conductivity and excellent leveling even on complex geometries.

Applications

Copper plating serves as a versatile solution across various industries, playing a critical role in both functional and aesthetic applications. It is commonly used in:

Electrical and electronic devices where conductivity is crucial

Automotive parts requiring a smooth, corrosion-resistant base

Plumbing and sanitary components that need enhanced bonding

Jewelry manufacturing to serve as a base layer before gold or silver finishes

Decorative hardware and metal furniture to provide a bright and smooth surface

Key Features

Our copper plating formulation is designed to deliver consistent plating performance while minimizing process variation and waste.

High conductivity ensures excellent electrical performance

Strong adhesion to base metals like steel, zinc, and brass

Bright, smooth finish for decorative applications

Fine grain structure suitable for multi-layer plating

Deep throwing ability to cover recessed or complex shapes

Compatible with a wide range of substrates and part sizes

Technical Performance

The plating bath is based on an acid copper solution, which is maintained at optimal conditions for efficient deposition and controlled growth. This solution works effectively in temperature ranges between 20°C to 35°C and supports adjustable current density, offering flexibility in thickness and finish based on the application.

Typical specifications include:

pH Range: 0.2 – 1.0

Copper Purity: >99.9%

Deposition Rate: 0.25 to 1.0 microns/min

Additives: Brighteners, wetting agents, and grain refiners included

Our in-house quality control and R&D teams continuously test each batch for purity, consistency, and compatibility to meet customer-specific requirements.

Safety & Environmental Care

Tahir Chemicals places strong emphasis on eco-safe formulations and responsible chemical handling. Our copper plating chemicals are designed to comply with national environmental regulations and workplace safety standards. We offer guidance on:

Safe handling and storage

Effluent and waste management

Personal protective equipment (PPE) usage

Environmental compliance procedures

Safety & Environmental Care

Tahir Chemicals places strong emphasis on eco-safe formulations and responsible chemical handling. Our copper plating chemicals are designed to comply with national environmental regulations and workplace safety standards. We offer guidance on:

Safe handling and storage

Effluent and waste management

Personal protective equipment (PPE) usage

Environmental compliance procedures

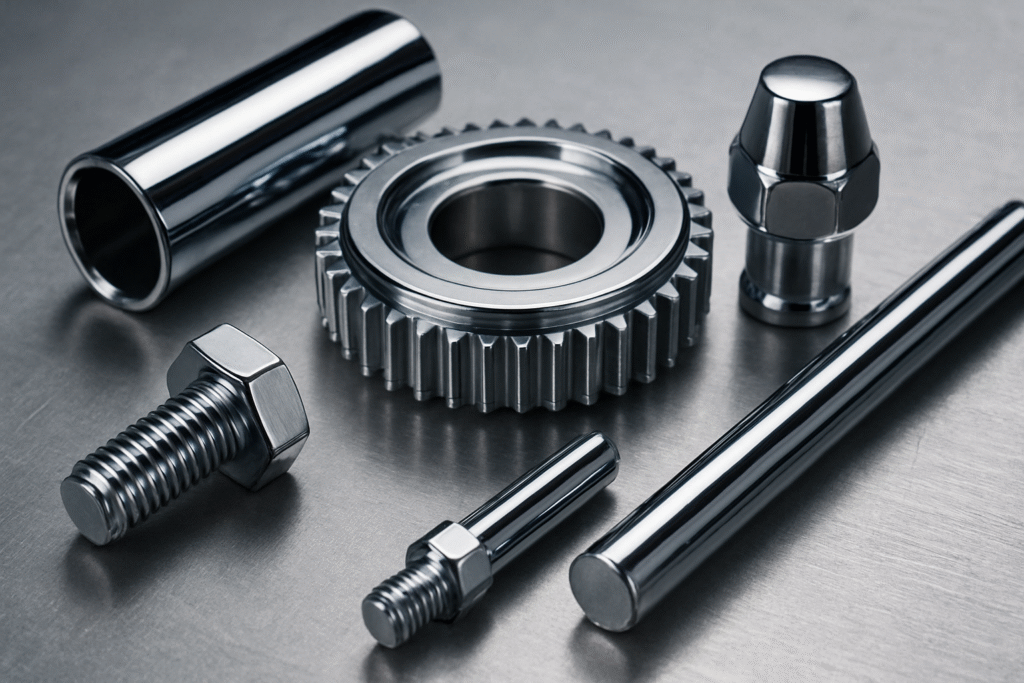

Nickel Plating Solution

Product Overview

Tahir Chemicals offers a high-quality Nickel Plating Solution formulated to deliver durable, uniform, and highly corrosion-resistant coatings. Nickel plating is widely used both as a standalone protective finish and as an intermediate layer beneath chrome or other metals. Our solution supports a range of industrial applications where hardness, wear resistance, and a bright metallic finish are essential.

Whether applied in barrel or rack plating systems, this solution provides smooth, level surfaces with strong adhesion, making it ideal for parts that undergo heavy use or need precise surface integrity.

Applications

Nickel plating plays a crucial role in enhancing both function and appearance across various industries. It is widely used in:

Automotive and engine components requiring wear resistance

Electronic connectors and terminals that demand conductivity and strength

Sanitary and plumbing fittings for aesthetic finish and durability

Tools and hardware that need enhanced corrosion protection

Jewelry and decorative items requiring a bright, elegant look

Key Features

Our nickel solution is designed to perform consistently even in demanding industrial environments.

Provides a bright, semi-bright, or matte finish depending on formulation

Excellent corrosion and wear resistance for long service life

Forms a hard, smooth, and uniform deposit

High compatibility with steel, brass, zinc die-cast, and copper

Reliable coverage for both simple and intricate part geometries

Technical Performance

The plating solution performs well under controlled bath conditions, providing stable and efficient metal deposition with precise thickness control.

Operating Temperature: 45°C – 65°C

pH Range: 3.5 – 5.0 (depending on bath type)

Current Density: 2 – 10 A/dm²

Deposit Hardness: 200 – 600 VHN (varies by additive and heat treatment)

Additives: Levelers, brighteners, and stress reducers

The bath can be customized for bright nickel or satin finishes depending on end-use requirements.

Safety & Environmental Care

Our nickel plating chemicals are developed with safety and environmental standards in mind. All solutions comply with relevant national regulations and include clear instructions for safe usage, disposal, and storage.

We assist our clients in implementing:

Safe chemical handling procedures

Ventilation and PPE requirements

Sludge and wastewater treatment practices

Bath life monitoring for reduced waste

Chrome Plating Solution

Product Overview

Tahir Chemicals offers a premium-grade Chrome Plating Solution designed to provide brilliant, hard, and corrosion-resistant finishes for both decorative and industrial applications. Known for its mirror-like shine and surface durability, chrome plating is ideal for components that demand both high aesthetic value and mechanical protection.

Our formulation ensures uniform thickness, high surface hardness, and excellent resistance to wear, oxidation, and tarnish. Whether used on automotive trims, sanitary fittings, or precision tools, our chrome solution delivers long-lasting results under demanding conditions.

Applications

Chrome plating is widely applied across industries for its distinctive appearance and functional benefits. It is commonly used in:

Automotive parts like rims, bumpers, and handles

Sanitary and bathroom fittings for a reflective, water-resistant finish

Tools and machinery parts that require wear resistance

Furniture hardware and decorative metal items

Key Features

Our chrome solution offers high hardness, excellent luster, and robust protection in a single layer.

Produces a mirror-bright finish

Extends service life by resisting corrosion and abrasion

Excellent coverage and leveling on detailed parts

Suitable for steel, brass, and copper substrates

Technical Highlights

Operating Temperature: 45°C – 60°C

Current Density: 2 – 8 A/dm²

Finish Type: Bright or hard chrome (available upon request)

Additives: Brighteners and catalysts pre-mixed for ease of use

Zinc Plating Solution

Product Overview

Tahir Chemicals’ Zinc Plating Solution is formulated to provide excellent corrosion resistance and surface protection for a wide range of industrial components. Zinc plating serves as a sacrificial coating, protecting base metals—especially steel and iron—from rust and oxidation. Its cost-effectiveness and reliability make it one of the most widely used electroplating processes in both heavy and light industries.

Our zinc solution is easy to apply, provides uniform coverage, and ensures strong adhesion even on complex part geometries. It is ideal for high-volume operations where performance and economy must go hand-in-hand.

Applications

Zinc plating is a preferred choice in multiple sectors where metal parts require long-lasting, affordable protection:

Fasteners and bolts used in construction and machinery

Automotive parts such as brackets, housings, and underbody components

Tools and hardware that operate in high-moisture environments

Sanitary fittings and metal enclosures needing corrosion resistance

Key Features

Our solution delivers consistent, bright to matte finishes depending on client requirements and offers effective coverage for parts with varying thicknesses and designs.

High corrosion resistance with sacrificial protection

Uniform zinc deposit with smooth finish

Compatibility with post-treatments like chromating (yellow, blue, black)

Ideal for steel, iron, and cast components

Technical Highlights

Operating Temperature: 20°C – 30°C

Recommended pH: 4.5 – 6.0 (acid zinc), 12.5+ (alkaline zinc)

Finish Options: Bright, blue, or matte zinc finish

Application Methods: Rack and barrel plating supported

Tin Plating Solution

Product Overview

Tahir Chemicals’ Tin Plating Solution offers a reliable and efficient surface finish that is both functional and visually appealing. Tin plating is widely used in the electronics, food, and medical industries due to its excellent solderability, corrosion resistance, and non-toxic nature. Our tin plating solution is designed to deliver consistent coatings with high brightness and smoothness, making it suitable for delicate components and high-precision work.

The deposit produced is ductile, highly conductive, and provides a safe contact surface, especially for electrical parts and food-grade applications.

Applications

Tin plating is the preferred choice where conductivity, safety, and solderability are key performance indicators. Common applications include:

Electrical connectors and terminals for low-resistance current flow

Printed circuit boards (PCBs) and other electronic components

Food-grade containers and utensils for non-toxic protection

Medical instruments and surgical tools requiring high purity and resistance

Key Features

Our formulation ensures smooth, bright deposits with easy process control for small and large batches alike.

Excellent solderability for electronic assembly

Non-toxic and food-safe surface properties

Resistant to tarnish and environmental degradation

Available in bright and matte finishes

Technical Highlights

Operating Temperature: 20°C – 30°C

Recommended pH: 4.5 – 6.0 (acid zinc), 12.5+ (alkaline zinc)

Finish Options: Bright, blue, or matte zinc finish

Application Methods: Rack and barrel plating supported

Gold and Silver Electroplating Solutions

Product Overview

Tahir Chemicals’ Gold and Silver Electroplating Solutions are developed to deliver premium decorative and functional finishes with unmatched brilliance, conductivity, and corrosion resistance. These precious metal plating solutions are formulated for industries where aesthetics meet performance—such as jewelry, electronics, luxury hardware, and high-end decorative applications. Our plating formulas ensure smooth, even deposition with long-lasting luster and minimal maintenance.

Both gold and silver coatings offer excellent surface quality and are customizable for thickness, brightness, and hardness based on the customer’s process and end-use.

Applications

These solutions are ideal for applications where visual impact, conductivity, and oxidation resistance are crucial. Common use cases include:

Jewelry and luxury accessories for elegant, lasting finishes

Electronic components such as connectors, switches, and circuit boards

Religious items, medals, and commemorative pieces

High-end hardware, cutlery, and decorative fittings

Key Features

Our gold and silver electroplating solutions are engineered to produce highly reflective, uniform coatings that are both attractive and functional.

Exceptional conductivity (especially with silver) for electronic applications

Corrosion and tarnish resistance with protective overlays

Bright and uniform appearance with customizable tone

Stable bath chemistry suitable for consistent production

Technical Highlights

Operating Temperature: 40°C – 60°C (gold), 20°C – 30°C (silver)

Thickness Range: Adjustable from 0.1 to 5 microns

Finish Types: Bright, satin, or antique gold/silver

Recommended Substrates: Copper, brass, nickel, and silver

Plating Additives

Product Overview

Tahir Chemicals’ Plating Additives are specialized chemical agents designed to enhance the performance, stability, and appearance of electroplating baths. These additives play a vital role in improving the efficiency and quality of the plating process, enabling smoother finishes, better brightness, controlled deposit thickness, and consistent coverage. Whether you’re plating with copper, nickel, chrome, zinc, or precious metals, our additives are engineered to meet a wide range of industrial demands.

Our formulations are compatible with most standard plating systems and can be tailored for specific process types, such as rack or barrel plating, depending on the substrate and the finish required.

Applications

Plating additives are essential across all sectors where electroplating is used, including:

Automotive and electronic component manufacturing

Hardware and tool surface finishing

Decorative coating processes

Jewelry and sanitary fittings production

They are applied in the bath alongside the primary metal salts to control grain size, reduce internal stress, improve brightness, and regulate leveling.

Key Features

Our additives help maximize productivity and coating performance across various plating operations.

Enhances brightness and surface leveling

Improves adhesion and corrosion resistance

Controls deposit stress to prevent cracks or blistering

Extends bath life and operational consistency

Supports uniform coating on intricate or recessed surfaces

Technical Highlights

Operating Temperature: 40°C – 60°C (gold), 20°C – 30°C (silver)

Thickness Range: Adjustable from 0.1 to 5 microns

Finish Types: Bright, satin, or antique gold/silver

Recommended Substrates: Copper, brass, nickel, and silver

Brighteners and Activators

Product Overview

Tahir Chemicals’ Brighteners and Activators are essential performance enhancers for modern electroplating systems. These specialty chemicals are formulated to improve the quality, consistency, and efficiency of metal deposits. Brighteners work by refining the grain structure of the deposited metal, resulting in highly reflective, smooth, and uniform finishes. Activators, on the other hand, play a critical role in surface preparation, ensuring that the substrate is properly conditioned to receive the plating layer without impurities or adhesion issues.

Used together or independently depending on the process, these additives help achieve superior aesthetic results, reduce plating defects, and maintain the stability of electroplating baths.

Applications

Brighteners and activators are widely used across plating processes for:

Copper, nickel, and chrome plating systems

Zinc and tin processes to enhance brightness and coverage

Jewelry and decorative item production

Electronics and automotive parts where high gloss and smoothness are required

Pre-treatment steps to activate passive metal surfaces

Key Features

These additives are formulated for consistent performance under industrial operating conditions.

Produces bright, glossy finishes with improved leveling

Minimizes pitting, streaks, and haze in finished layers

Ensures better adhesion between substrate and deposit

Works efficiently at low concentrations with long bath life

Suitable for manual and automated plating systems

Technical Highlights

- Compatible Processes: Acid and alkaline baths

- Dosage: Based on surface area and bath condition (technical guidance provided)

- Application: Added during bath setup and maintained regularly

- Packaging Sizes: Small sample bottles to industrial drums

Why Tahir Chemicals?

With over 30 years of expertise in electroplating chemistry, Tahir Chemicals formulates brighteners and activators that not only improve finish quality but also enhance process reliability. Backed by expert advisory and lab-tested performance, our additives ensure consistent results, minimal rework, and excellent surface appeal across all plating jobs.